What Is LCD ( Liquid Crystal Display )

Liquid Crystal Displays, more commonly referred to as LCDs, are a technology I deeply admire because of their passive nature. Unlike other displays, they don’t emit their own light. Instead, they utilize the surrounding ambient light to present images. And the icing on the cake? They achieve this using minimal power. This unique trait has propelled LCDs to the forefront, making them the top choice in scenarios where energy efficiency and portability are of paramount importance.

How do LCD works?

At the heart of these displays lies the ‘liquid crystal’ – a fascinating organic compound that carries properties of both liquids and crystals. When I peer into this liquid form, I observe the rod-like molecules neatly aligned side by side. What’s even more fascinating is the ability to use electric fields to manipulate these molecules. Nowadays, the most commonly used type of liquid crystal in LCDs is the ‘Twisted Nematic’ or TN. I’d recommend taking a look at the provided figure for a better understanding of this molecular alignment.

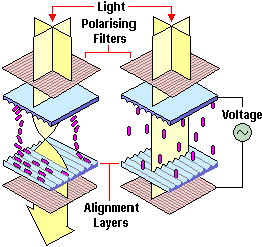

Imagine, if you will, two substrates constructing a thin, flat vessel filled with this liquid crystal solution. These inner surfaces of our vessel are delicately coated with a specific polymer, meticulously buffed to ensure the liquid crystal molecules orient themselves in the direction of this buffing. For devices employing the Twisted Nematic approach, the buffing on the two surfaces is orthogonal, which causes a 90-degree twist in the liquid crystal molecules from one end to the other – again, the provided figure should help elucidate this structure.

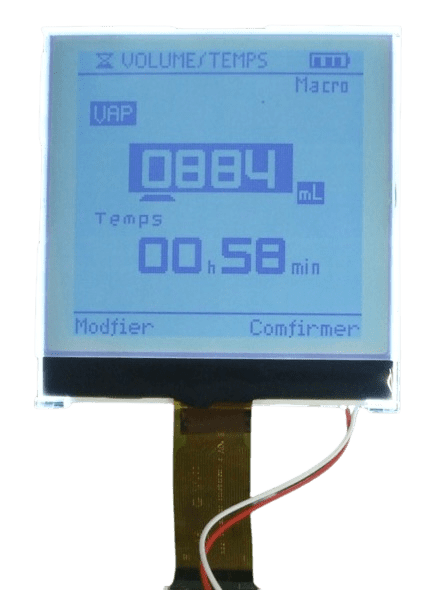

Within LCD displays, transparent electrical conductors are meticulously layered on both sides of the glass, directly interfacing with the liquid crystal solution. These conductors, serving as electrodes, are crafted from Indium-Tin Oxide (ITO). Once a specific driving signal is introduced to these electrodes, it establishes an electric field throughout the cell. As a result, the liquid crystal molecules align themselves following the direction of this electric field. Consequently, any linearly polarized light entering the cell continues its trajectory unaltered, eventually getting absorbed by an analyzer positioned at the rear. This phenomenon manifests to the viewer as distinct black characters set against a subtle silvery-gray backdrop. In the absence of the electric field, the molecules revert to their natural twisted state, approximately a 90-degree twist.

This display mode, which showcases a sharp contrast between the characters and their background, is commonly known as a positive image, reflective viewing mode. Advancements in this fundamental LCD technology, particularly by incorporating multiple electrodes with selective voltage application capabilities, enable the creation of diverse display patterns.

How LCDs are Constructed?

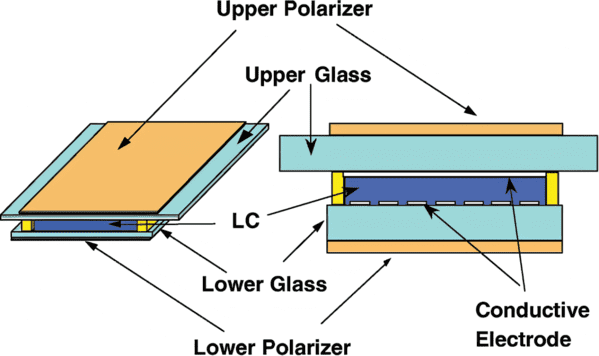

1. The Glass Panels:

At the heart of the LCD are two parallel glass panels. These panels are thin, clear, and provide structural integrity to the overall display. They serve as the house for all the other components.

2. Transparent Electrical Conductors:

Layered onto these glass panels are transparent electrical conductors. Typically made from Indium-Tin Oxide (ITO), these conductors act as electrodes. They play a pivotal role in setting up the electric field which interacts with the liquid crystal solution sandwiched between.

3. Liquid Crystal Solution:

Sandwiched between the glass panels and the electrodes is the actual liquid crystal solution. These molecules have a unique property: when exposed to an electric field, they can change their alignment, controlling the passage of light.

4.Polarizing Filters:

On the outer side of each glass panel, there are polarizing filters. These filters only allow light waves vibrating at a particular angle to pass through, and they’re crucial for the LCD’s operation. As the liquid crystal molecules change their alignment in response to electric fields, they twist the light passing through, effectively modulating which light gets through the polarizers.

5. Backlight:

For LCDs that aren’t reflective, such as those in computer monitors or televisions, there’s a backlight placed behind the liquid crystal layers. This backlight illuminates the display, making the images and text visible. The most common types of backlights are CCFL (Cold Cathode Fluorescent Lamp) and LED (Light Emitting Diode).

6. Color Filters:

In colored LCD displays, there’s an additional layer of color filters aligned with the liquid crystal cells. These filters separate the light into red, green, and blue pixels, the primary colors that combine in varying intensities to produce the multitude of colors we see on our screens.

LCD technology & type

Twisted Nematic (TN)

The TN panel is the oldest and most common type of LCD panel. Its name stems from the twisted nature of its liquid crystal molecules which typically have a 90-degree twist. I’ve found the TN panel to be best suited for applications that don’t require wide viewing angles or precise color representation, such as certain computer monitors or budget devices. This is because it offers faster response times, making it ideal for fast-paced gaming, but has limited viewing angles and color depth.

Super-Twisted Nematic (STN)

Progressing from TN panels, we move onto STN displays. As the name implies, Super-Twisted Nematic panels twist the liquid crystal molecules more than the standard 90 degrees, usually between 180 to 270 degrees. This increased twist provides a higher contrast than TN, making it more readable in direct sunlight. I personally saw the massive utility of STN in the early days of mobile phones and pagers due to its low power consumption and improved legibility over TN displays. However, STN screens usually display slower response times and often introduce a color-casting effect.

Film Super-Twisted Nematic (FSTN)

FSTN displays can be considered an enhanced version of the STN. By adding a film layer, the display quality of STN panels is improved. I often recommend FSTN displays for applications that need higher contrast and wider viewing angles than STN, without migrating to the more expensive TFT technology. They are commonly found in car dashboards, industrial instruments, and some older models of digital watches.

Vertical Alignment (VA)

Vertical Alignment panels are a step up from the traditional TN panels in terms of color accuracy and viewing angles. In a VA panel, liquid crystal molecules align vertically to the panel when voltage is not applied, giving deeper blacks and higher contrast ratios. I particularly appreciate VA panels for television screens and computer monitors where wider viewing angles and improved color reproduction are crucial.

Thin-Film Transistor (TFT)

Perhaps the pinnacle of LCD technology, TFT displays, use a separate transistor for each pixel, allowing for faster response times and better color reproduction. Whenever I think of high-end computer monitors, laptops, and modern smartphones, TFT panels come to mind. They’re the most common type of LCD these days due to their versatility and superior image quality. The power consumption, however, is relatively higher compared to TN and STN, which is a trade-off for its impressive visual output.

Conclusion

As I reflect on the intricate dance of molecules and electricity that brings LCD displays to life, my admiration for this technology only deepens. From the delicate alignment of liquid crystal molecules sandwiched between protective glass panels to the subtle manipulation by electric fields, the world of LCDs is a testimony to human ingenuity. It’s no small wonder that they dominate various facets of our digital lives.

When we talk about LCDs, we aren’t just referencing a singular technology but an evolution of sorts. The journey from the basic TN panels to the sophisticated TFT ones illustrates our relentless pursuit for perfection. Each type, from the sun-friendly STN to the contrast-rich VA, finds its unique place and purpose in our gadgets and devices. The trade-offs between power consumption, viewing angles, and color depth reflect our efforts to tailor the technology to specific needs.

In essence, LCDs aren’t just screens. They’re a blend of chemistry, physics, and electronics. They’re art canvases that come alive at the touch of a button, bringing worlds to our fingertips. Whether you’re reading an e-book under the sun or engrossed in a high-definition movie on your latest smartphone, remember that you’re witnessing the magic of liquid crystals at play.

I firmly believe that the LCD technology, though mature, still holds promise for further innovations. As we continue to integrate technology deeper into our lives, the display’s importance will never wane. It’s a beautiful time to be in this field, and I am eager to see where we’ll venture next with LCDs.